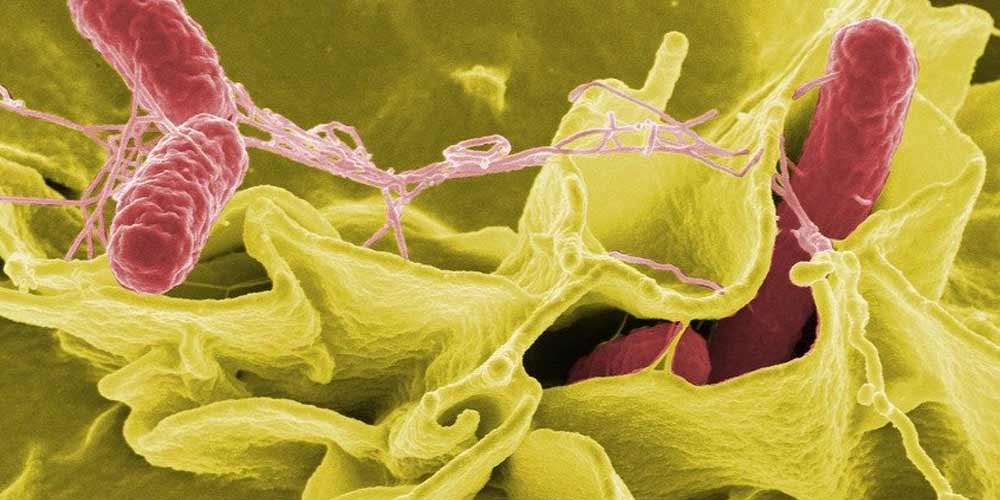

Pathogens

The choice of the appropriate sampling method for the surface analysis of pathogens.

Prevention against listeria in equipment and production areas

Methods for Salmonella and Listeria analysis

The control of pathogens in foodstuffs is a major point in food safety. Testing laboratories and food companies have to perform diagnostic tests in order to detect contamination in any stage of the production chain of foodstuffs.

Salmonella or Listeria monocytogenes can cause your business closure

Recent cases of food poisoning (in 2019) due to Salmonella and Listeria show that appeared in the media have highlighted the importance of the control and analysis of pathogens (Listeria monocytogenes and Salmonella) and the consequences for consumers and companies in the food sector. They have been serious cases, like 5 dead from eating sandwiches in the hospital in the UK, 5 dead by consuming trout and smoked salmon or French Government stopped the production of a cheese company after finding Listeria in their products.

Listeria and Salmonella test in a simple and safe device without laboratory

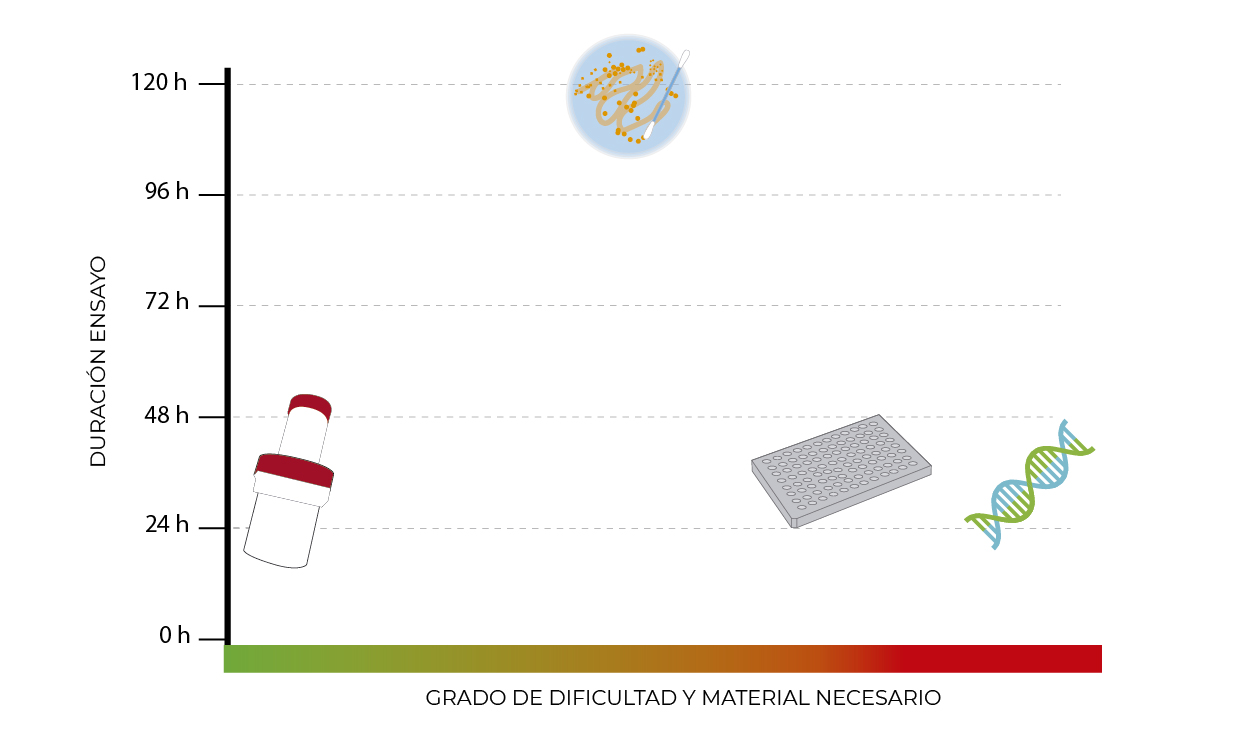

The new MicroLab device can detect the presence of Salmonella or Listeria in food samples in a simple and safe manner. The new system integrates all the assay steps into a single disposable device. It facilitates and speeds up the results while minimizing production losses in case of contamination. Listeria and salmonella are two of the main concerns of the food safety sector. During the period of 2014-2017 there were 1,139 outbreaks of food salmonellosis in Spain and more than 1800 cases of infection in the EU by listeria were reported. In order to manage and improve self-inspection, the company Zeulab is launching onto the market “an analysis device, all in one, which will allow food businesses to autonomously self-inspect without risk of contamination in a simple and reliable way,” notes CEO Dr. Pedro Razquin Zeulab. MicroLab has two product lines, one for detecting Salmonella and one for Listeria monocytogenes. Microlab integrates the three phases of the analysis onto one device (enrichment, detection and inactivation). The process is performed as follows: the device is hermetically closed after introducing the sample, preventing any risk of contamination in the presence of positive samples. Once the enrichment stage has passed, 24 hours or 48 hours for Salmonella Listeria, the result is obtained in 15 minutes in a visually and easily interpretable manner. Once the text is complete, the device may be inactivated so that it can be disposed of in a safe way. The advantages of this new device include the ability to reduce/eliminate the risk and perform a first check for both those products that due to having a short life need fast results and companies that do not have their own laboratory and need fast results that enable them to start the transformation process of the product. It permits the application of the device on a wide variety of meat, dairy, egg and smoked products. Safety and risk of contamination are key elements in the reputation of food brands. Thanks to its simplicity and safety, food businesses will have a new safety system incorporated in their work processes, allowing them to analyze themselves without the need for an internal laboratory, an extra step in food safety.